Ship Windows

We know everything about ship windows

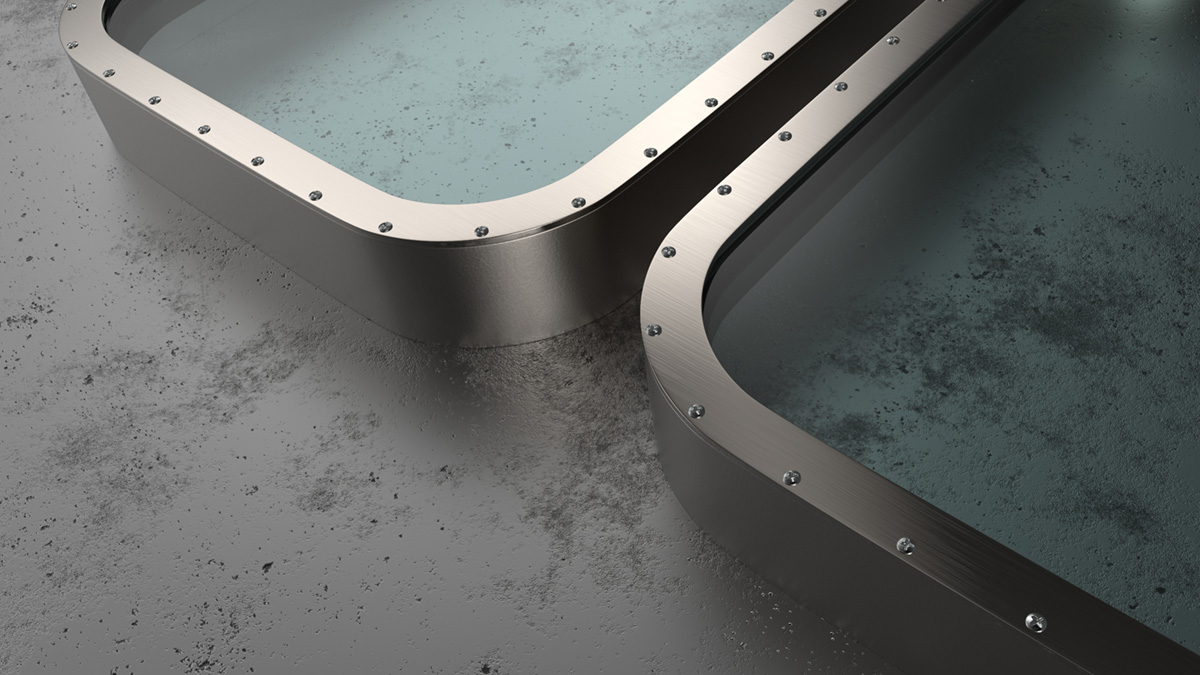

Designing and producing ship windows is a critical aspect of the marine industry. Ship windows are designed to provide the crew and passengers with a clear view of the outside world while also ensuring the safety of the vessel.

Ship windows – Fixed

installation method: welded, bolted, clamped

shapes available: rectangular, trapezoid, circular, oval, special

frame material: ST, SS, AL

glass retainer material: ST, AL, brass

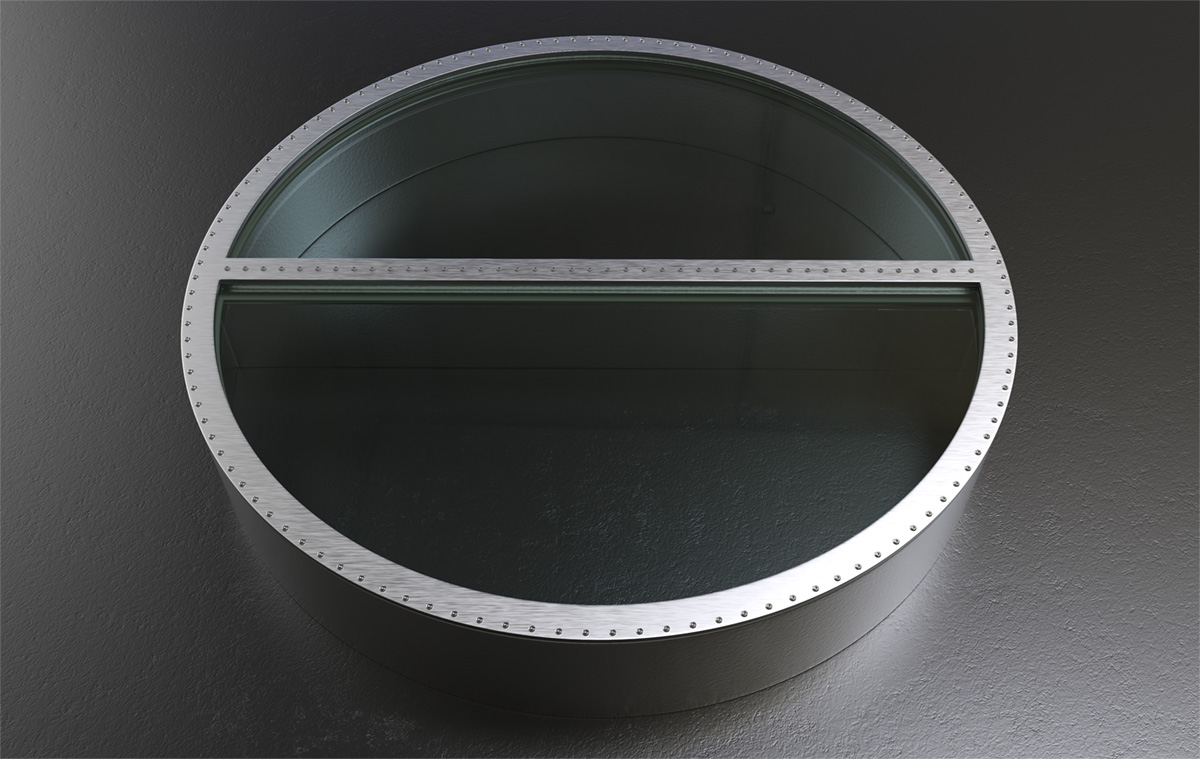

optional mulion: vertical, horizontal

options: external storm cover, deadlight

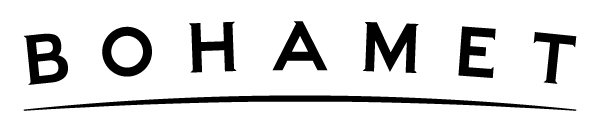

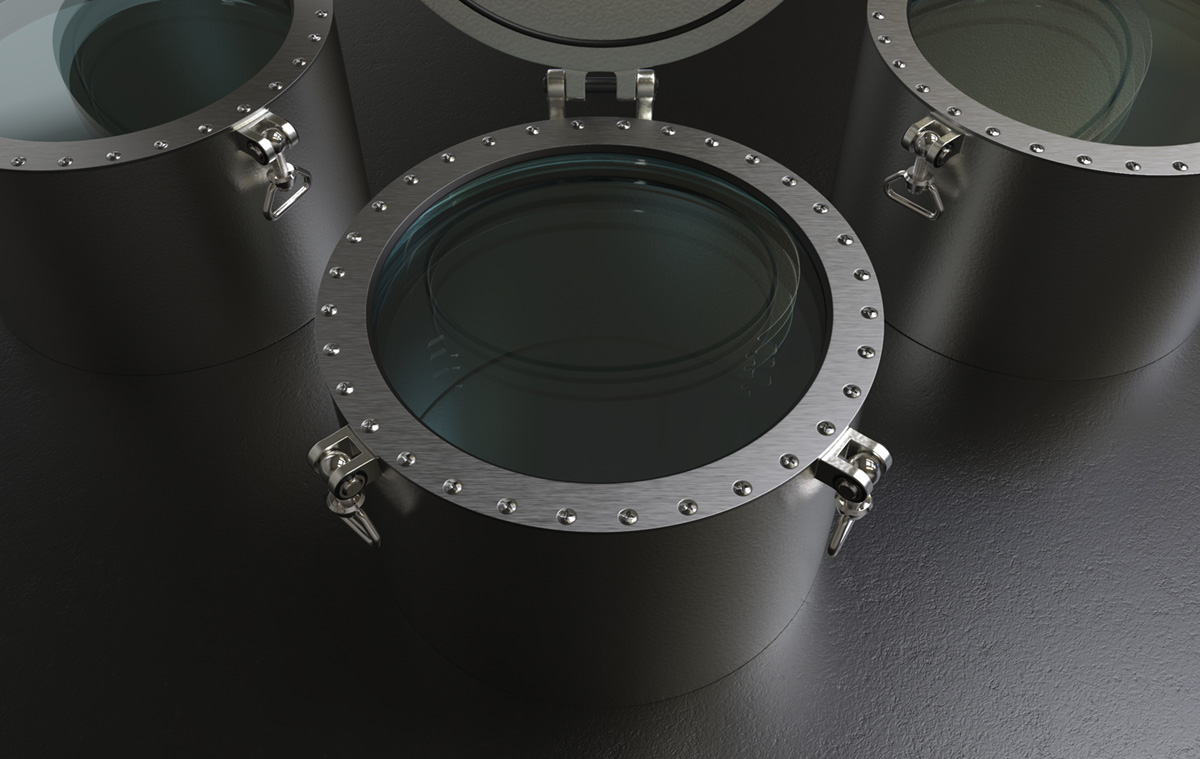

Side scuttles – Fixed

installation method: welded, bolted

frame material: ST, SS, AL

glass retainer material: ST, AL, brass

optional mulion: vertical, horizontal

options: external storm cover, deadlight

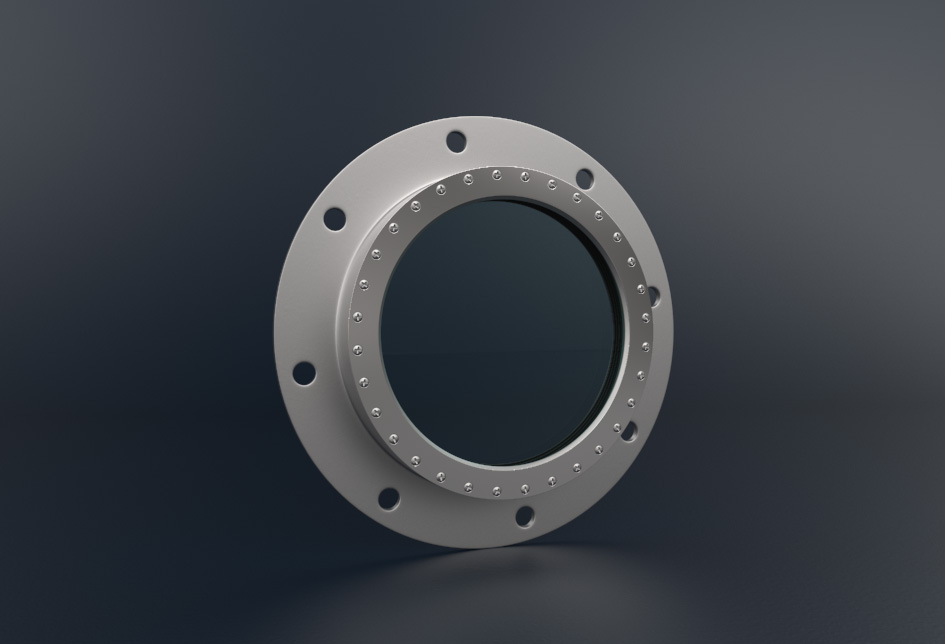

Ship windows – Opening

installation method: welded, bolted, clamped

shapes available: rectangular, trapezoid, circular, oval, special

frame material: ST, SS, AL

glass retainer material: ST, AL, brass

optional mulion: vertical, horizontal

options: external storm cover, deadlight

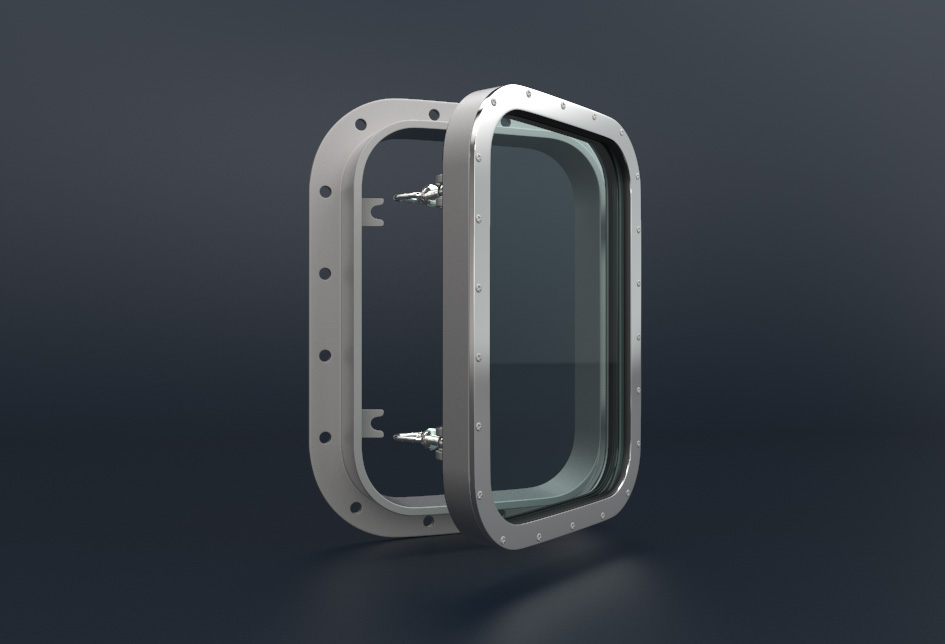

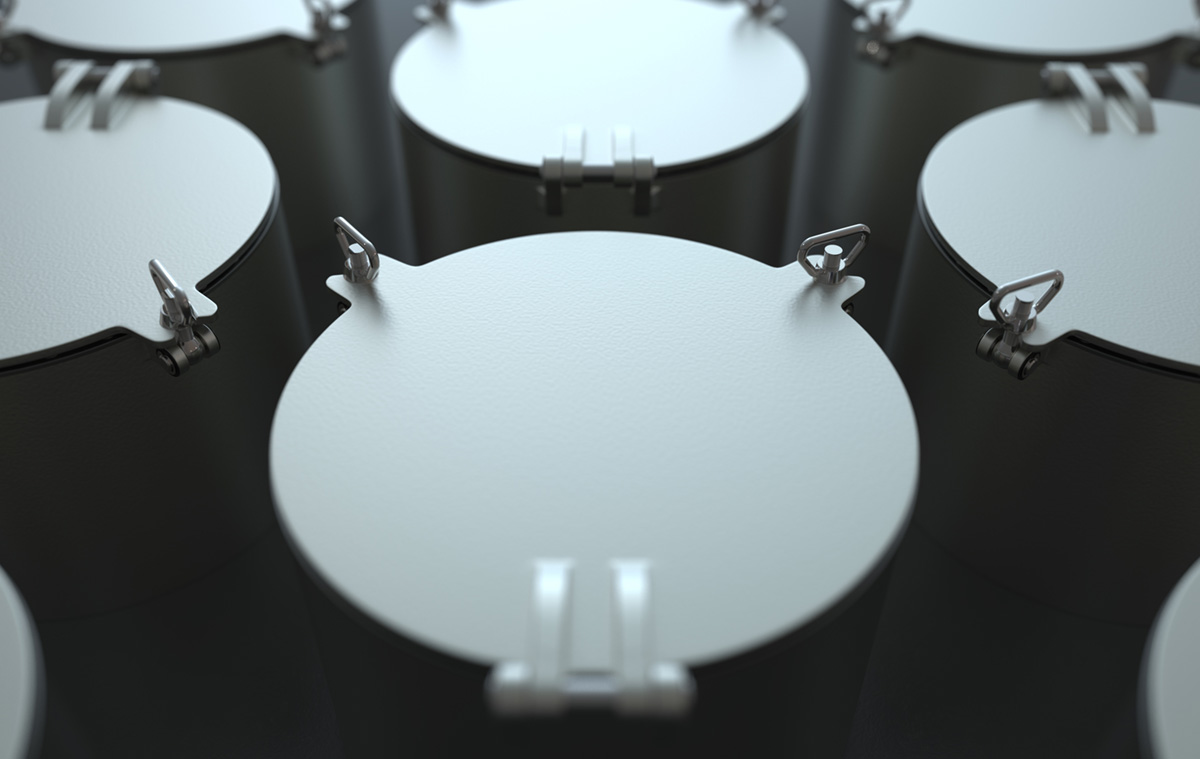

Side scuttles – Opening

installation method: welded, bolted

frame material: ST, SS, AL

glass retainer material: ST, AL, brass

optional mulion: vertical, horizontal

options: external storm cover, deadlight

Sliding windows – Opening

type: horizontal, vertical

installation method: welded, bolted

shapes available: rectangular, special

frame material: ST, SS, AL

glass retainer material: ST, AL, brass

Windows – Fixed

Fire rated

Fire rated

installation method: welded, bolted

shapes available: rectangular, trapezoid, circular, oval, special

frame material: ST, SS

glass retainer material: SS

optional mulion: vertical, horizontal

options: external storm cover, deadlight

fire-rating: A0, A30, A60

Side scuttles – Fixed

Fire rated

Fire rated

installation method: welded, bolted

frame material: ST, SS

glass retainer material: SS

optional mulion: vertical, horizontal

options: external storm cover, deadlight

Windows – Opening

Fire rated

Fire rated

installation method: welded, bolted

shapes available: rectangular, trapezoid, circular, oval, special

frame material: ST, SS

glass retainer material: SS

optional mulion: vertical, horizontal

options: external storm cover, deadlight

Side scuttles – Opening

Fire rated

Fire rated

installation method: welded

frame material: ST, SS

glass retainer material: SS

optional mulion: vertical, horizontal

options: external storm cover, deadlight

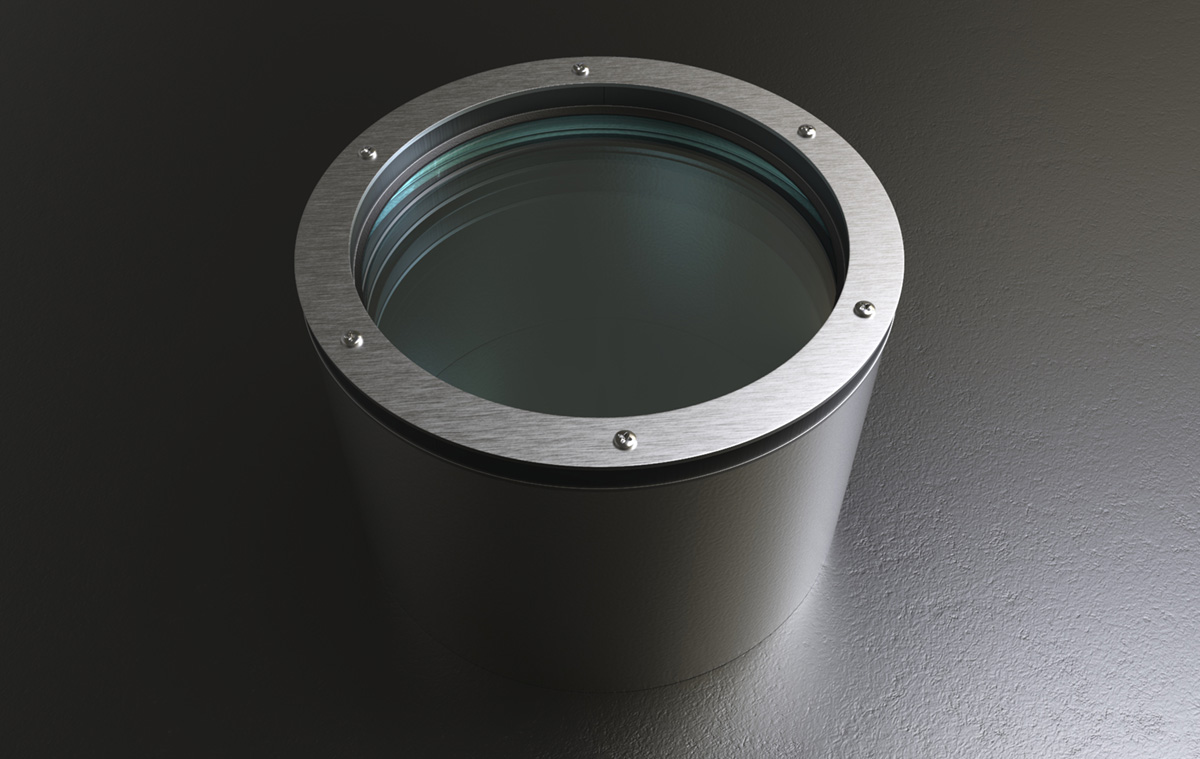

Materials

The materials used to produce ship windows must be able to withstand the harsh marine environment. Common materials used in ship window production include steel, stainless steel, aluminium, and brass. The surface of ship window frames is usually protected with a combination of appropriate primers and paints.

Design Considerations

When designing ship windows, several factors must be taken into consideration. Ship windows must meet strict safety and performance standards to ensure the safety of the crew and passengers onboard. This includes meeting requirements for visibility, impact resistance, and fire protection, as well as any specific regulations governing the use of certain materials or manufacturing techniques. As such, ship window production is highly specialized and requires advanced manufacturing equipment and techniques, as well as a deep understanding of the unique requirements and challenges of marine environments.

Manufacturing Techniques

The manufacturing process for ship windows involves several steps. First, the design is created using computer-aided design (CAD) software. This allows the designer to create a 3D model of the window, which can be adjusted and refined as needed. Ship window steel frames are typically produced using a variety of techniques, including cutting, bending, welding, and surface finishing. The exact manufacturing process will depend on the specific design requirements of the frame, as well as the size and shape of the window it is intended to support.

Cutting and Bending

The first step in producing a steel window frame is typically to cut and bend the raw material to the required shape and size. This may involve using specialized cutting tools, such as a plasma cutter or water jet, to cut the steel into the desired shape, as well as bending tools to create curves or other features as needed.

Welding

Once the individual components of the frame have been cut and shaped, they are typically welded together to create the final frame. This may involve using various types of welding techniques, such as MIG, TIG, or arc welding, to fuse the individual components together into a single, strong, and durable frame.

Surface Finishing

The window frame is usually prepared for assembly by screwing or welding to the steel board. The surface of the frame is usually treated with a combination of primers and paints or galvanized to improve its appearance and protect against corrosion.

Quality Control

Throughout the manufacturing process, quality control checks will typically be conducted to ensure that the finished frame meets the required specifications and safety standards. This may involve checking the size and shape of individual components, verifying the strength and durability of welded joints, and conducting various tests to assess the performance of the finished frame under different conditions. Quality control checks are performed throughout the manufacturing process to ensure that the window meets the required specifications and safety standards. Our products meet following requirements and standards – windows ISO-3903:1977 and sidelights ISO 1751:1977.